General Information

Figure 1 shows a steel arch bridge that is used by motorcycles, bicycles and pedestrians.

| Number of spans | 1 |

| Main span | ≅ 15 m |

| Arch rise | ≅ 1 m |

| Deck width | ≅ 2 m |

Support Types

Figure 2 shows a side view of the bridge.

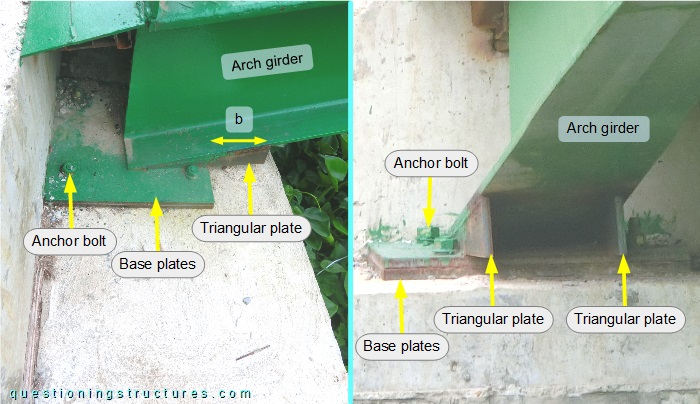

The arch girder has an I-section; the connections to the RC abutments (connections 1 and 2) are shown in figures 3 and 4, respectively.

| Side view | Front view |

The arch girder is connected to the abutment by two stacked base plates, four anchor bolts, and two triangular plates, which are welded under the flange width ends region and protruding from the base plates (length b).

| Side view | Front view |

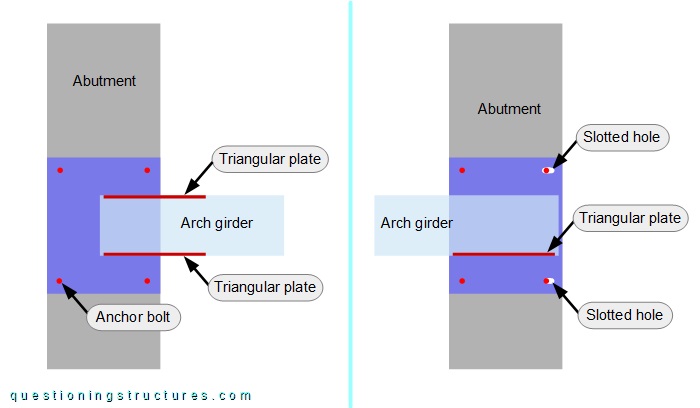

Connection 2 differs from connection 1; the arch girder is placed near the back edge of the base plates, and there is only one triangular non-protruding plate that connects the flange over a length of c. The arch girder and triangular plate are detached over a length of d. The two stacked base plates have two longitudinal slotted holes. Figure 5 shows a schematic layout of connections 1 and 2.

| Connection 1 | Connection 2 |

What type of support can be used for modeling connections 1 and 2?

Plastic Deformation

Figure 6 shows a side view of the bridge.

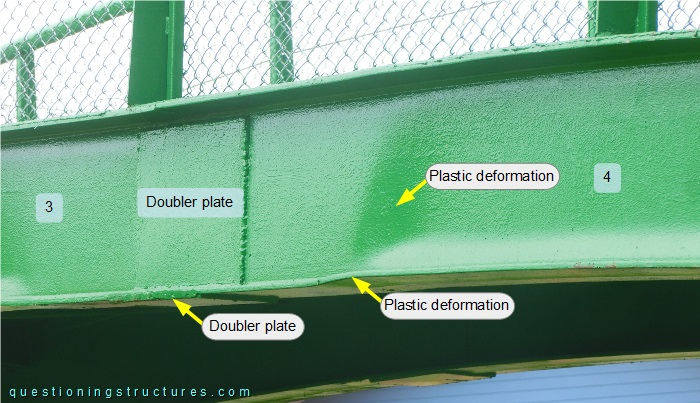

There are four I-sections (1 to 4) per side, which are connected by welding. Sections 1, 2, and 3 are about a sixth main span long, while section 4 is about a half main span long. The arch girder-to-arch girder connections are shown in figures 7 to 9.

The connection has vertical and horizontal doubler plates. Plastic deformation located in the top and bottom flanges of both sections is noticeable.

There is no plastic deformation.

Plastic deformation located in the bottom flange and web region on I-section 4 is noticeable.

What are some possible causes for the plastic deformations?

Bridge Entrances

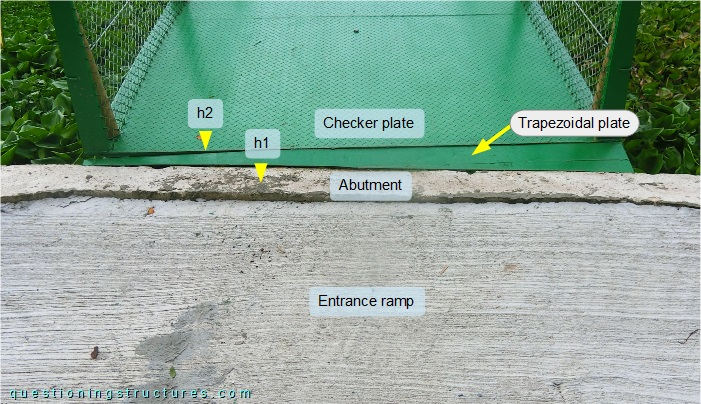

Entrances 1 and 2 are shown in figures 10 and 11, respectively.

There is a trapezoidal gap between abutment and deck, which is covered by a steel plate. The abutment and the opposite edge of the checker plate are about at the same elevation level (h1 ≅ h2).

The abutment and the edge of the checker plate are on different elevation levels (h2 > h1), and there isn't a trapezoidal gap between the aforementioned elements. There is also an elevation difference between the entrance ramp and the abutment, which is bridged by a sloped asphalt layer.