General Information

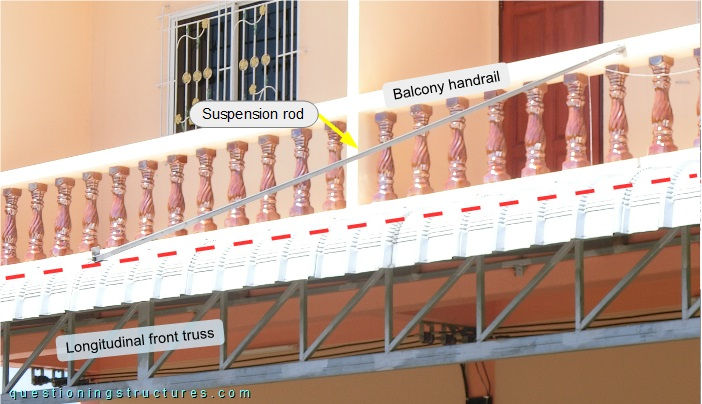

Figure 1 shows a steel canopy roof.

Suspension Rod

Figure 2 shows the canopy roof.

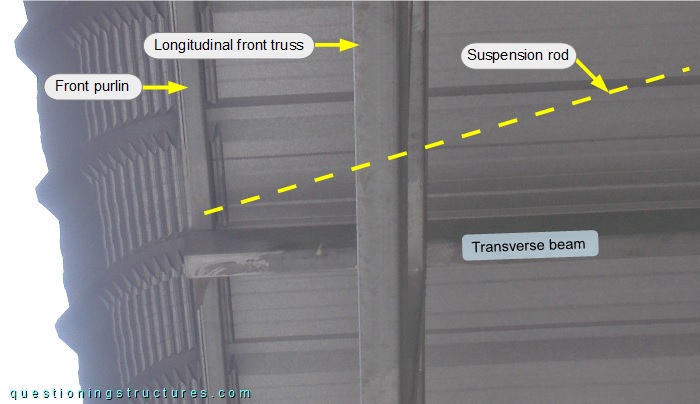

The steel structure consists mainly of two front columns, a longitudinal front truss, a single suspension rod (marked by the blue line), transverse beams, purlins, and metal roofing sheets. The span s ≅ 12 m, and the span b ≅ 3 m. Figure 3 shows the suspension rod.

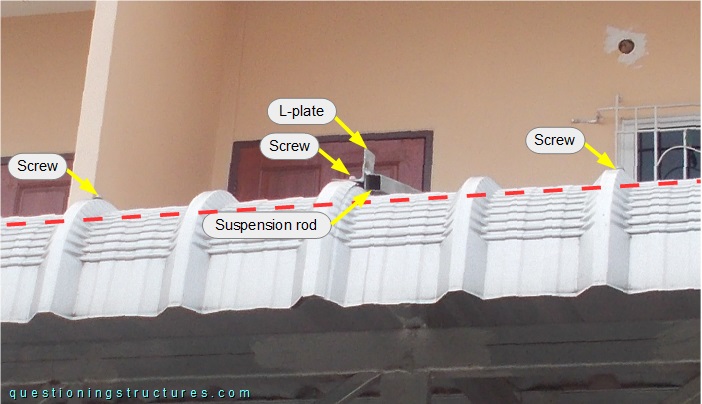

The suspension rod is made of a square hollow section and is placed in the mid-span region of the front truss; it connects the front purlin (marked by the red dashed line) with the balcony handrail. Figures 4 and 5 show a front and a bottom view of the connection between the suspension rod and the canopy roof.

The suspension rod is welded to an L-plate, which is connected to the front purlin by a sheet metal screw.

The transverse beam overhangs from the longitudinal front truss, and the front purlin is placed over its free end.

Does the canopy roof have a structural safety or serviceability problem without the suspension rod?

Connection Between Truss and Column

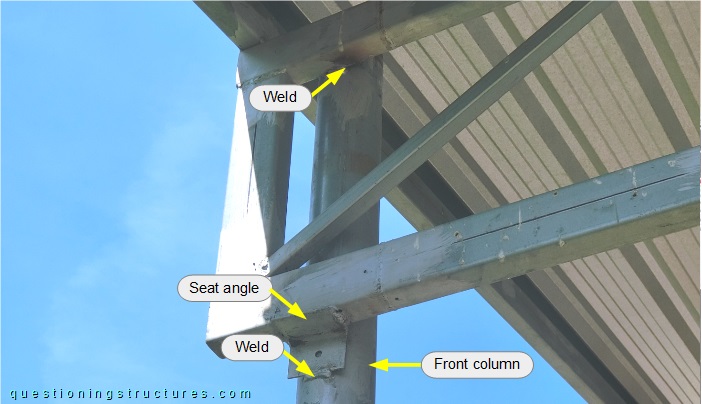

The front truss is connected to the front columns as shown in figure 6.

A truss chord is made of two square hollow sections placed one over the other and joined by welding, while a front column is made of a circular hollow section. The bottom chord is connected to the column by a welded seat angle, while the upper chord is welded directly to the column.

What are the main problems?