General Information

Figure 1 shows the construction site of a commercial building.

Long-Span Cold-Formed Steel Trusses

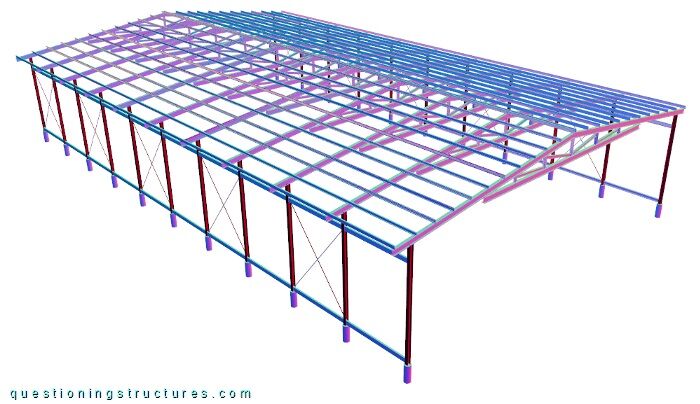

Figure 2 shows the building.

The roof structure consists of cold-formed steel (CFS) raised tie trusses, purlins, and metal roofing sheets, while the columns and cross-braces are made of hot-formed steel (HFS). The span s ≅ 20 m, the tie beam length l ≅ 12 m, the raise r ≅ 1 m, the roof pitch angle ɑ ≅ 8°, and the truss/column spacing ≅ 3.5 m. Figure 3 shows a front view of a truss sector.

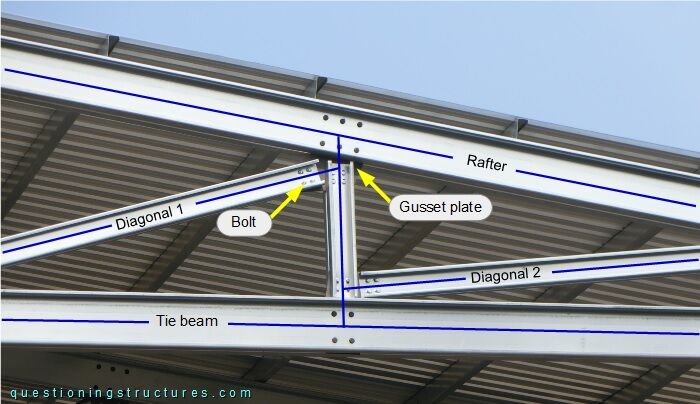

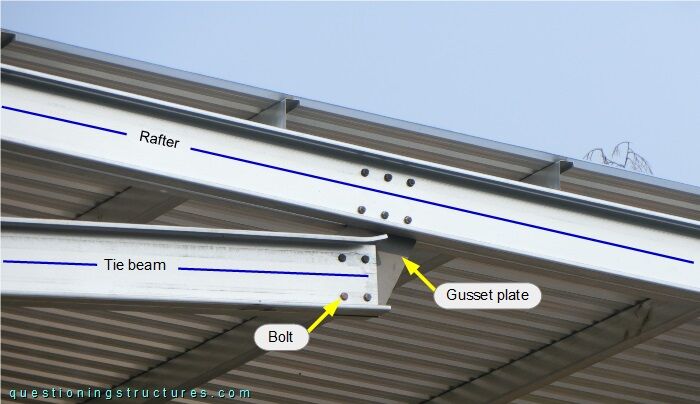

The truss members are made of two back-to-back lipped channels, while the nodes consist of bolted gusset plates. The inclination angle of diagonal 1 with respect to the tie beam is about 16°, while the inclination angle of diagonal 2 is about 6°. The truss nodes are eccentric, and the purlins are placed away from them. Figure 4 shows a front view of the tie beam to rafter connection, while figure 5 shows a schematic three-dimensional view of the structure.

How efficient are the above shown CFS raised tie trusses?