General Information

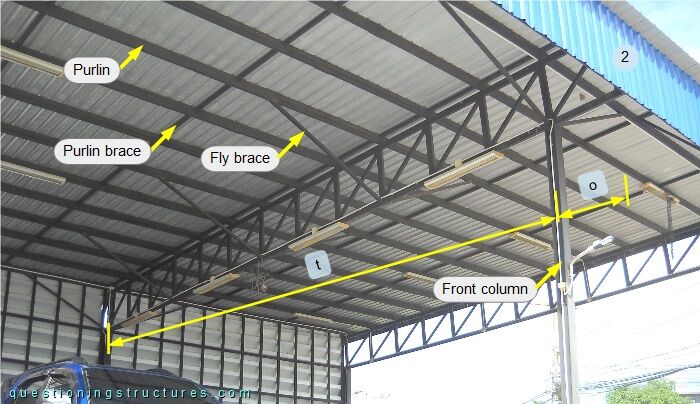

Figure 1 shows a freestanding steel carport.

The steel structure consists mainly of columns, a metal wall cladding system (installed on the back side), three trusses (marked by the numbers), purlins, purlin braces, fly braces, and metal roofing sheets. The distance between the columns l ≅ 7 m, and the distance t ≅ 10 m. The carport is in a snowless region.

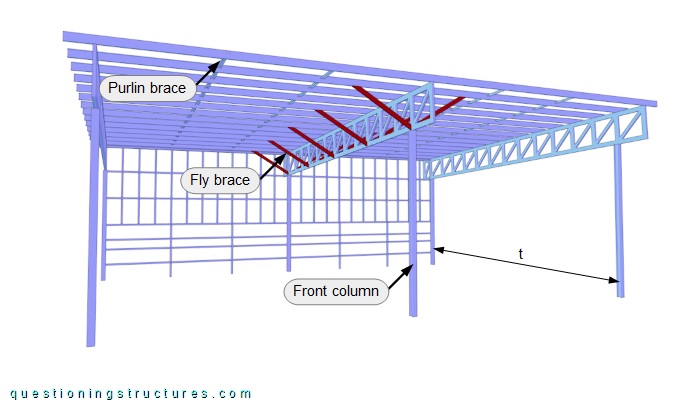

Fly Bracing

The central truss fly braced, as shown in figure 2.

The truss is supported by two columns (front and back) and overhangs on each side; the front overhang o ≅ 1 m, and the back overhang ≅ 0.5 m. The columns and the truss (bottom chord) are connected by cap plates. The fly braces are connected to the bottom chord of the truss and the bottom flanges of the purlins by welding. The columns are made of H-sections, the trusses and the fly braces are made of rectangular hollow sections, and the purlins and their braces are made of lipped channels. Figure 3 shows a schematic three-dimensional view of the structure.

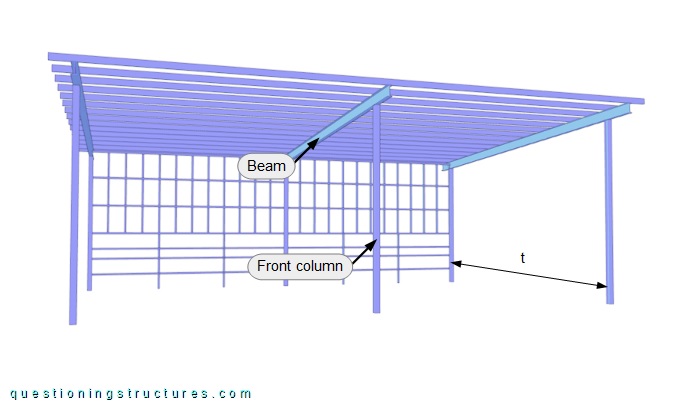

Figure 4 shows a schematic three-dimensional view of an alternative variant that uses beams instead of trusses and without fly- and purlin bracing.

The columns are made of H-sections, the beams are made of I-sections, and the purlins are made of rectangular hollow sections.

Which is the variant that probably uses fewer resources?